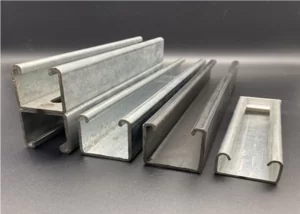

5 benefits of using galvanized steel pipes in construction

Using galvanized steel pipes in construction offers a multitude of benefits. From its sturdiness to its impressive lifespan, galvanized steel pipes are a great choice for construction projects both big and small. Not only do galvanized steel pipes offer an impressive strength-to-weight ratio and corrosion resistance, but they also come with a number of other advantages like low cost and easy installation compared to steel grating. In this blog post, we’ll explore the five key benefits of using galvanized steel pipes in construction.

1) Galvanized steel pipes are more durable than other types of pipe

When it comes to construction, durability is a crucial factor that can determine the longevity of a structure. Galvanized steel pipes are known for their high durability, making them a popular choice for various construction applications. Compared to other types of pipes, such as PVC or copper, galvanized steel pipes offer superior strength and resistance against wear and tear.

One reason for this is the unique galvanization process used in the production of these pipes. During the manufacturing process, the steel is coated with a layer of zinc, which serves as a protective barrier against corrosion and rust. This layer of zinc is bonded to the steel, creating a strong and long-lasting material that can withstand harsh environmental conditions.

In addition to their high durability, galvanized steel pipe are also capable of handling heavy loads. This makes them ideal for use in applications such as steel grating, where a strong and stable surface is required to support heavy equipment or machinery. Their durability also makes them a popular choice for underground plumbing systems, as they can withstand the pressure and weight of soil and other underground materials.

Overall, the use of galvanized steel pipes in construction provides numerous benefits, including durability, strength, and resistance to corrosion. When it comes to building structures that will stand the test of time, galvanized steel pipes are a reliable and practical choice for contractors and builders alike.

2) They’re less likely to corrode or rust

One of the major advantages of using galvanized steel pipes in construction is that they’re less likely to corrode or rust. This is due to the fact that galvanization involves coating the steel with a layer of zinc, which provides a protective barrier against moisture and other elements that can cause corrosion.

Corrosion can weaken pipes and cause leaks or even failures, which can be costly to repair or replace. With galvanized steel pipes, however, you can have peace of mind knowing that your pipes will last longer and require less maintenance. This is especially important for outdoor applications where pipes may be exposed to the elements, such as in steel grating or other outdoor structures.

Steel grating, in particular, can benefit from the use of galvanized steel pipes as they are often exposed to water and other harsh elements. Galvanized steel pipes can withstand these conditions and prevent the grating from becoming damaged or corroded. Additionally, galvanized steel pipes can also be used in underground applications where moisture levels are high, such as in sewage or drainage systems.

Overall, the use of galvanized steel pipes offers numerous benefits, including increased durability, ease of installation, and aesthetic appeal. So, whether you’re building a steel grating or constructing a building, consider using galvanized steel pipes to ensure that your structures stand the test of time.

3) They’re easier to install

In addition to being more durable and resistant to corrosion, galvanized steel pipes are also easier to install. Because they’re lighter than other types of pipe, such as cast iron or copper, they’re easier to handle and transport to the job site. Plus, their threaded ends make them simple to connect together with fittings, reducing the need for welding or soldering.

Galvanized steel pipes also work well with steel grating, which is often used in industrial applications or for flooring in walkways and platforms. Steel grating provides a slip-resistant surface that’s strong enough to support heavy loads, and galvanized steel pipes can be used as supports or for handrails. The ease of installation and compatibility with steel grating makes galvanized steel pipes a versatile choice for a variety of construction projects.

4) They’re more aesthetically pleasing

Galvanized steel pipes offer more than just functional benefits. They also provide an aesthetic appeal that can enhance the look of a building or outdoor structure. The smooth, shiny finish of galvanized steel pipes can add a touch of modern elegance to any project.

Moreover, galvanized steel pipes are commonly used in combination with steel grating to create unique and attractive designs. Steel grating, which is made of parallel steel bars, is often used as a walkway or platform. When combined with galvanized steel pipes, the result can be a visually striking pattern that complements the surrounding architecture.

Additionally, galvanized steel pipes come in a variety of sizes and shapes, making them versatile in their applications. Whether used in industrial or residential settings, these pipes can be customized to meet any design aesthetic.

5) Galvanized steel pipes can be used in a variety of applications

From water transportation and drainage systems to gas and oil pipelines, galvanized steel pipes have a broad range of uses in the construction industry. They are also widely used in structural applications such as handrails, guardrails, and scaffolding. Their durability, corrosion resistance, and ease of installation make them a popular choice among construction professionals. Additionally, galvanized steel grating, which is made of galvanized steel, is often used in industrial flooring, catwalks, and stair treads due to its anti-slip properties and resistance to heavy loads. With so many benefits and applications, it’s no wonder galvanized steel pipes and tubes remain a staple in the construction industry.